Project Description

Sao Vang – Dai Nguyet field is located in Block 05-1b & 05-1c in the Nam Con Son Basin, offshore of Vietnam, approximately 350km southeast of Vung Tau with a water depth of approximately 120m. Sao Vang – Dai Nguyet field is currently managed by Idemitsu Gas Production Vietnam (IGPV) and the production capacity is approximately 175 MMSCFD.

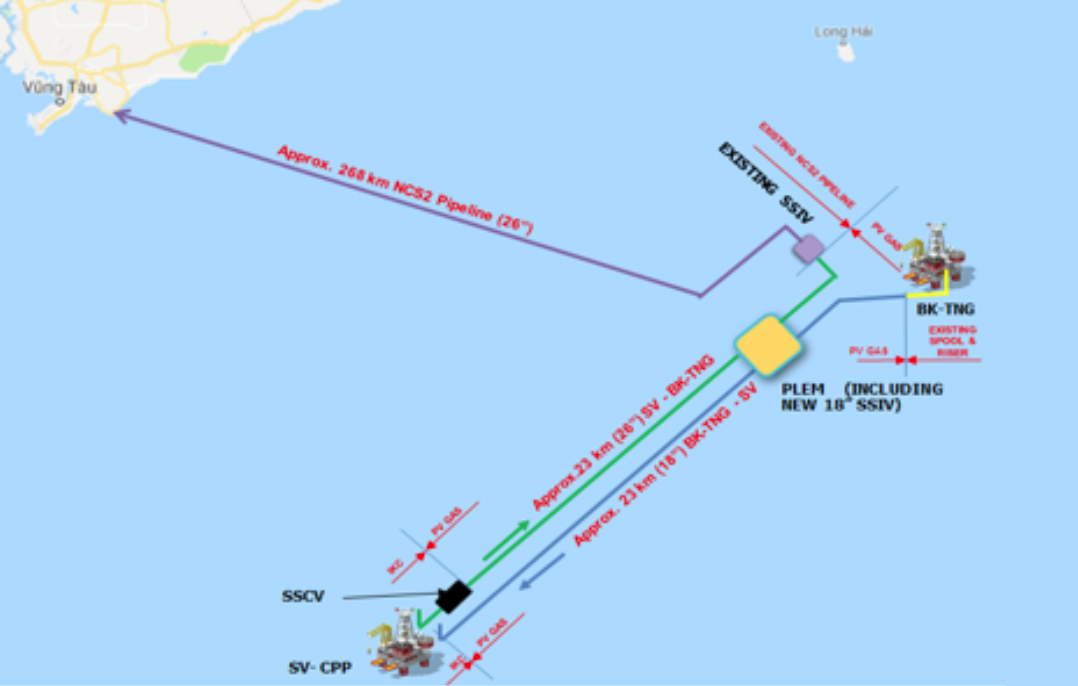

In order to gather and transport gas from Sao Vang – Dai Nguyet field as long as Thien Ung – Dai Hung field, PV GAS is developing the project “Sao Vang – Dai Nguyet Gas pipeline” (hereinafter referred to as Project) with a total capacity of 2-3 billion m3/year for southeast Area of Vietnam.

PetroVietnam Gas Joint Stock Corporation (PV Gas) has completed its investment research and deployed the project of gas gathering and transporting pipeline project of Sao Vang – Dai Nguyet gas field (SV-DN) in 2019 and 2020 to collect and transport gas of Thien Ung field/condensate gas of Dai Hung field (TU-DH) from BK-TNG Wellhead Platform to Sao Vang Central Processing Platform (SV-CPP) for compression into high-pressure gas with SV-DN gas and further transport ashore through the Nam Con Son Pipeline Phase 2 (NCS2).

The pipeline system including:

- 26inch Sao Vang – Nam Con Son 2 (SV-NCS2): ~22km length;

- 18inch Thien Ung – Sao Vang (TU-SV): ~23km length.

The offshore installation campaign including PLEM installation and pre-commissioning of two (2) pipelines, 26inch Sao Vang – Nam Con Son 2 and 18inch Thien Ung – Sao Vang pipelines started on June 22, 2020, and finished on September 29, 2020. PetroVietnam Technical Services Joint Stock Corporation (PTSC) has been awarded by PV GAS as an independent contractor to implement the entire Engineering, Procurement, and Construction (EPC) of the Project. Both pipelines, 26inch Sao Vang – Nam Con Son 2 and 18inch Thien Ung – Sao Vang had been duly handed over to PV GAS on September 29, 2020, for PV GAS to conduct gas-in operation for the 26inch pipeline. on 11/16/2020 and an 18inch pipeline on 16/12/2020.

Sope Of Project

PTSC, the EPC Contractor, after completing the pre-commissioning of both pipelines, had carried out the handover of the 26inch Sao Vang – Nam Con Son 2 and 18inch Thien Ung – Sao Vang pipeline systems to the Representative of Client, PV GAS PMC on September 29, 2020, for the PV GAS to perform the commissioning (gas-in operation) to bring the pipelines into operation stage.

- The first route: 26inch Sao Vang – Nam Con Son 2 pipeline was commissioned by PV GAS on 11/16/2020 and no abnormalities were recorded and reported. The 26inch pipeline was well operated up to satisfaction of PV GAS’ operating conditions.

- The second route: the 18inch Thien Ung – Sao Vang pipeline was commissioned by PV GAS on December 16, 2020, but an abnormality detected: the gas received at the SV-CPP has high dew point and pressure difference reported between 2 ends of 18inch pipeline at SV-CPP and BK-TNG, then seawater is sighted at Slug Catcher on SV-CPP. Leakage(s) was suspected of occurring for the 18inch Thien Ung – Sao Vang pipeline.

PV GAS PMC, Representative of Client, had required PTSC to conduct underwater ROV survey for the 18inch Thien Ung – Sao Vang pipeline to investigate an abnormality (suspected leakage) occurred to the pipeline. Result of ROV survey had recorded a leakage at 18inch flange connecting PLEM’s Ball Valve and Tie-in Spool No. 10 in the area near BK-TNG, Thien Ung field.

The scope of the Project is described as shown in Figure below.

And then, PV GAS PMC had also assigned PTSC to carry out the scope of work on rectification of the leakage found at 18inch flanges (between PLEM and Tie-in Spool No. 10) belong to 18inch pipeline Thien Ung – Sao Vang (hereinafter referred to as Work) includes the following main items:

- General project management and administration, deployment and execution of work;

- Re-assessment of detailed design and procedure development for leakage repair including new design (if any);

- Rent and purchase equipment and materials for repairing the leakage including fabrication and modification of Tie-in Spool No. 10 (if needed);

- Charter and mobilize marine construction vessels and SAT diving equipment to the offshore worksite (Thien Ung field) to perform leakage repair;

- Perform underwater repairing work of leakage by diving support vessel with SAT divers including refurbishment and the new addition of support for Tie-in Spool No. 10;

- Carry out de-watering, cleaning, and drying for 18inch pipeline and 18inch flange leak test with Kamos gasket;

- Carry out an as-built survey to record the current condition of the facilities after repairing;

- Other construction works upon request and instructions from Client/Company (if any);

- Acceptance test and as-built documentation.

SHELF has been contracted to provide diving and ROV services to assist in the rectification of the leak as well as pre-commissioning of the pipeline.